Lead all phases of new product development of 230 new items across 10 new product collections

Lead engineering efforts from design concept through Production Test Run and assisted the manufacturing team with the launch quantity production phase

Lead all phases of new product development of 230 new items across 10 new product collections

Lead engineering efforts from design concept through Production Test Run and assisted the manufacturing team with the launch quantity production phase

Modified the design of the door cladding molding of the Ford Escape for the Chinese Market. Worked closely with the design studio, the North American supplier, and the Chinese launch team and suppliers to develop a design that would be both feasible and appealing to the high end Chinese consumers

Redesigned the cowl vent grille (also known as leafscreen) for the Ford Fusion when a major water ingestion issue was discovered at the prototype stage. The biggest challenges of this redesign were the following:

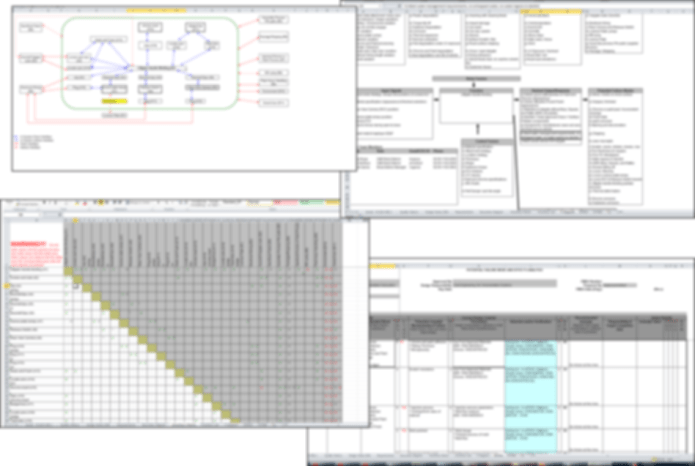

To ensure the robustness and quality the design, product engineers must deliver an evidence book with quality, robustness and failure mode analysis documentation for each of their components. The idea behind this project was to create comprehensive templates for the components developed by the exterior trim team. The templates contain information for all possible iterations of a component and can be modified by the product engineer to fit the specific conditions of their design. Using the templates would make the delivery of the evidence book more efficient for the engineers compared to starting from scratch.